The critical points of operating VFFS packing machine

Vertical filling sealing and packing machines (VFFS) are widely used in the food, pharmaceutical, and other industries to pack products efficiently and accurately.

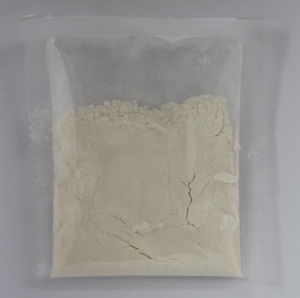

The critical points of operating a powder vertical packing ,filling and sealing machine can vary depending on the specific machine ,however ,here some general points to keep in mind:

Product consistency: Ensure that the powder being packed is consistent in terms of texture, density, and particle size. This will help ensure accurate filling and sealing.It also help to smooth the material feed into measuring device easily.

Proper Calibration: Calibration of the machine is crucial to ensure that it can accurately measure the right amount of powder for each package. The calibration should be checked regularly to avoid any deviations in the filling weight.

Correct Filling Technique: The machine’s filling technique should be adjusted according to the type of powder being filled to ensure that the powder is filled accurately and without any spillage.The ensure

Sealing Quality: The sealing quality of the machine should be monitored regularly to ensure that the packaging is airtight and prevents the powder from leaking or spilling,So that to prolong the shelf-life of the products

Machine settings: Properly adjust the machine settings, such as the filling speed, sealing temperature, and pressure, to ensure optimal performance and operating smoothly .

Regular Maintenance: The machine should be regularly maintained to prevent any mechanical failures or malfunctions that could affect the filling or sealing process.

Cleanliness: The machine should be kept clean and free from any debris or contaminants that could affect the quality of the powder or the packaging.

Proper Training: The machine operators should be properly trained on how to operate the machine and handle any issues.

Post time: Mar-13-2023