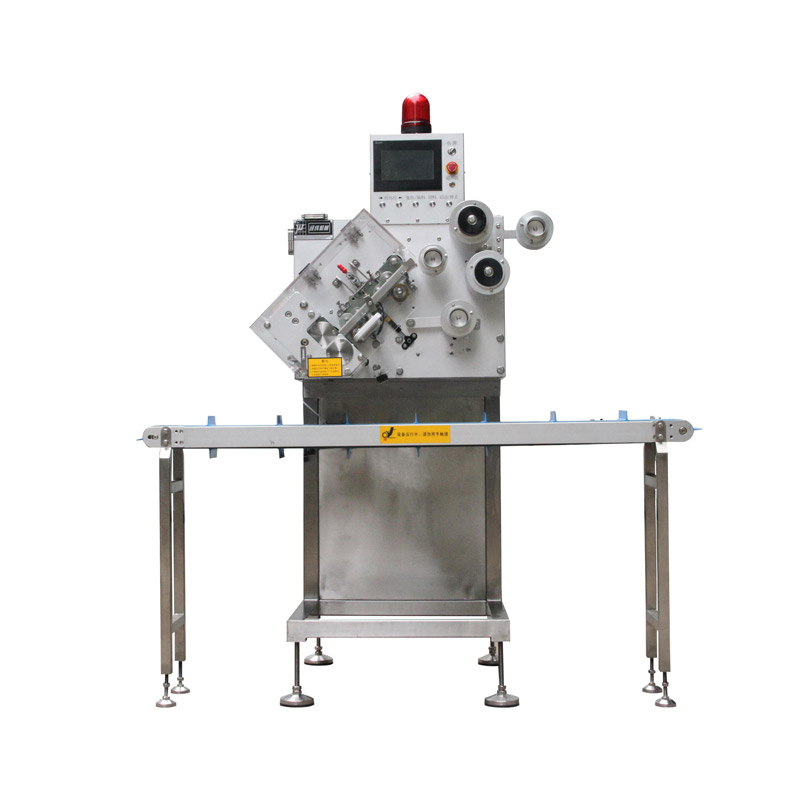

Wholesale Price Kefai Automatic Vertical Filling and Sealing Machine for Sachet Liquid Sauce Honey Oil Packing Machine Price

“Based on domestic market and expand overseas business” is our enhancement strategy for Wholesale Price Kefai Automatic Vertical Filling and Sealing Machine for Sachet Liquid Sauce Honey Oil Packing Machine Price, Top quality will be the key factor with the company to stand out from other competitors. Seeing is Believing, want more data? Just trial on its merchandise!

“Based on domestic market and expand overseas business” is our enhancement strategy for China Automatic Vertical Filling and Sealing Machine and Honey Sauce Packing Machine, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to offer best products and solutions for our customers.

This model allow the auto counting online and setting the number of continuous cutting, measuring the sachet length by ultrasonic sensor, easy to setting and change bags with different length. It’s always work with the high speed pouch layer in a fully automatic production line with highly capacity, to reduce the labors and improve accuracy. Easy to adjust the cutting position, cutting force and the dispensing position. It’s precise control, easy operation and maintain, and high efficiency,so it’s very popular by our customers.

| Technical parameters | |

| Product Application | powder , liquid , sauce , desiccant ,etc |

| Pouch size | 50mm≤W≤100mm 50mm≤L≤120mm |

| Dispensing speed | Max : 300 bags/min(bag length = 70mm) |

| Detection mode | Ultrasonic |

| Feeding mode | Upstairs feeding or downstairs feeding |

| Power | 1.5Kw,single phase AC220V ,50HZ |

| Machine Dimensions | (L) 1000mm×(W) 760mm× (H) 1300mm |

| Machine weight | 200Kg |

Features:

|

|

“Based on domestic market and expand overseas business” is our enhancement strategy for Wholesale Price Kefai Automatic Vertical Filling and Sealing Machine for Sachet Liquid Sauce Honey Oil Packing Machine Price, Top quality will be the key factor with the company to stand out from other competitors. Seeing is Believing, want more data? Just trial on its merchandise!

Wholesale Price China Automatic Vertical Filling and Sealing Machine and Honey Sauce Packing Machine, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to offer best products and solutions for our customers.

Features:

1. Servo drive control of the cutting and bag feeding to achieve the precise control then to achieve the high speed cutting.

2. Allow the auto counting online and setting the number of continuous cutting. To adjust the cutting position, cutting force and the dispensing position.

3. Adopting the ultrasonic sensor to measure the bag length to meet the various packing and change the product easily.

4. PLC controller and friendly interface to make operation simply.

5. Advanced fault feedback to make the maintenance easily.