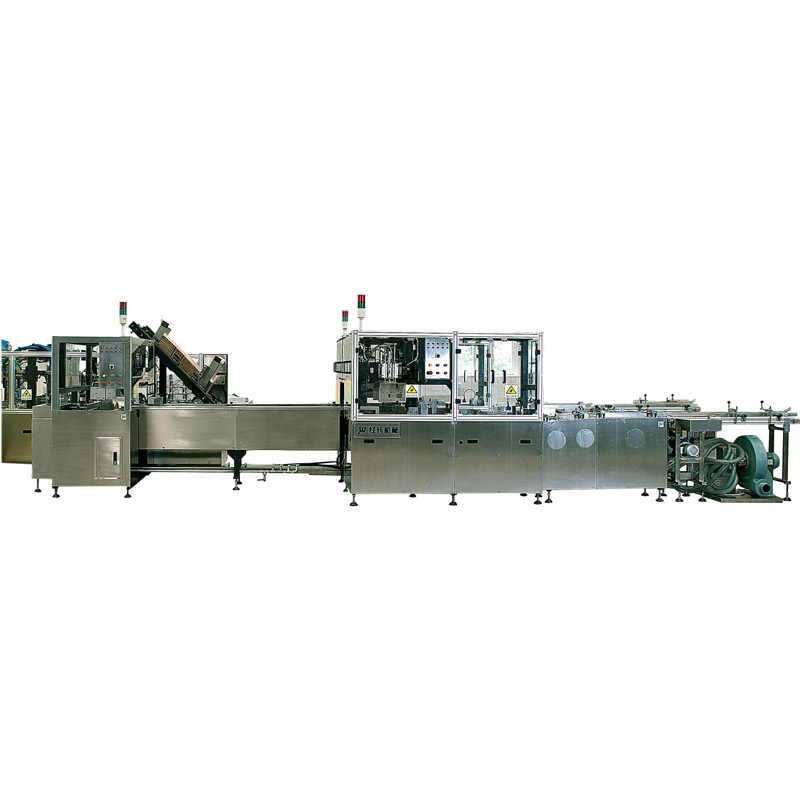

Automatic Bag Noodle Case Packer-ZJ-QZJ20

| Production capacity | 18 cases/min (24 lanes) |

| Station | Encasement station: 11; Length of station: 571.5 mm, Conveyor station: 16; Length of station: 533.4 mm |

| Box size | L: 320-450mm, W: 320-380mm, H: 100-160mm |

| Glue melting machine power | 5KW |

| Power | 15kw, three-phase five line, AC380V, 50HZ |

| Compressed air | 0.4-0.6Mpa, 700NL/min (max) |

| Machine dimensions | (L)10500mm x(W)3200mm x(H)2000mm (Exclude entrance conveyor) |

| Height of carton discharge | 800mm±50mm |

Features

1. Convenient operation, management, reduction of operator and labor intensity, and improvement of work efficiency.

2. The machine is with stable and reliable running,automatic arrangements in order and perfect sealing of the carton and smoothly artistic features.

3. It is especially suitable for matching with the packaging assembly line to realize fully automatic production and packaging.

It is suitable for automatic packing of instant noodles and instant noodles.

Following are some works for understanding:

Bag Infeed: This is the starting point of the machine where the bagged noodles are loaded onto the infeed conveyor. The bags are usually pre-filled with noodles and sealed.

Bag Opening: The bags are then opened using a bag opener that uses suction cups to grip the bag and open it up, allowing the noodles to flow out.

Carton Erecting: The machine then erects cartons and sets them up for filling. The cartons are usually flat-packed before they are loaded into the machine.

Filling: The opened bags of noodles are then filled into the cartons using a filling system. The system uses a series of belts, funnels, and chutes to guide the noodles into the carton.

Carton Closing: Once the cartons are filled, the flaps are folded down

Carton Conveying: The cartons are then conveyed to the next station for further processing.

Quality Control: At this stage, the cartons are checked for proper sealing and correct noodle weight.

Carton Stacking: The filled and sealed cartons are then stacked on pallets in preparation for shipping.

Control System: The entire process is controlled by a programmable logic controller (PLC), which monitors and controls the various components of the machine.

Overall, an automatic bag noodle carton casing machine is an efficient and reliable way to package bagged noodles into cartons. The machine can handle a high volume of noodles and can package them quickly and accurately. It is an essential piece of equipment for food manufacturers who need to package their products in a cost-effective and efficient manner.